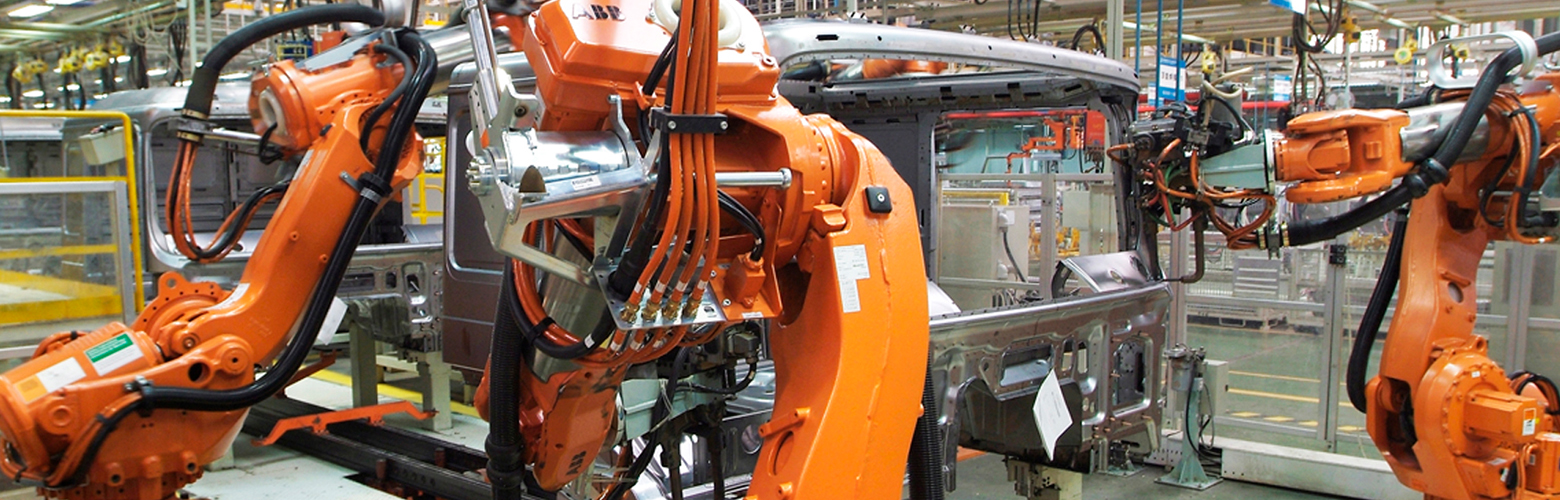

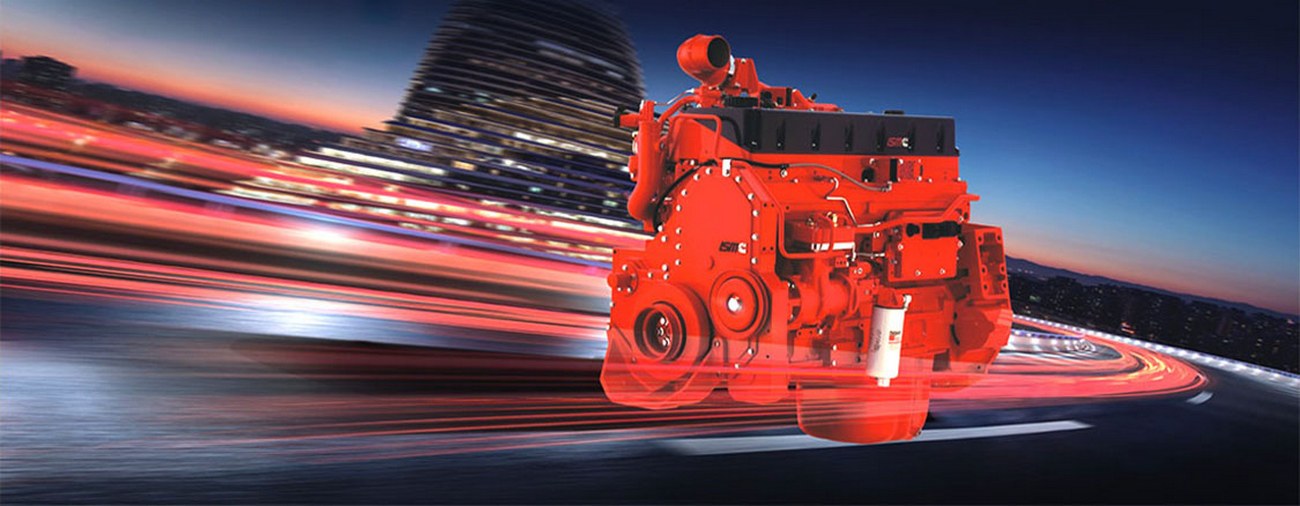

As the flagship of the world-renowned Cummins product series, ISM 11 heavy-duty diesel engine that is fully electronically controlled, ranging from 345 to 440 hp, perfectly matches various types of heavy trucks, buses, special-purpose vehicles, special vehicles, construction machineries and other vehicles.

With reliable quality and superior performance of this well-known product in the world, Cummins won many partners all over the world. The B10 service life of Engine is intended up to 2 million km. No overhaul occurs within one million kilometers mileage after being verified though 450 billion km mileage.

Reliable Design and Assured Quality

With a simple and effective structure, the modular design of Cummins ISM 11 Engine effectively reduces weight and improves operational efficiency. Both the surface and the interior of cylinder are reinforced by reinforcing bars, ensuring better strength and rigidity than the competing products while maintaining the light weight.

Mid-stop cylinder liner avoids deformation and prevents from abnormal wear between the piston and the liner. Articulated piston withstands higher mechanical and thermal load, eliminating knocking at low temperature and scuffing at high temperature, Cummins Celect fuel system (low-pressure fuel line) has been designed to eliminate risks of fuel leakage.

Large amount of oil into and from the fuel injector prevents injector from stuck, And, the flowing fuel also cools down the ECM -the brain of the Engine,extending the service life of ECM.

By unique combination of viscosity sensor, pressure regulator and relief valve, the lubrication system automatically regulates the engine oil pressure, ensuring lubrication effects in all seasons.

The package design of engine oil thermostat, radiator and bypass valve guarantees an optimal working condition for the Engine and effectively prolongs the oil change interval. 4-step pressure regulator for turbocharging system can improve response speed to prevent overheart, overspeed and abnormal wear

Reliable Design and Assured Quality

With a simple and effective structure, the modular design of Cummins ISM 11 Engine effectively reduces weight and improves operational efficiency. Innate Safety Reliving Your Anxiety Industry leading Jacobs braking system for Cummins Engine works safe and efficiently, free of maintenance.

Up to 326 hp of braking power reduces over 60% of brake wear, lowering maintenance cost.Jacobs is only 20 kg in weight and be used to replace water spraying tank. Reducing the vehicle weight means increasing vehicle load capacity and improving efficiency.

Mid-stop cylinder liner avoids deformation and prevents from abnormal wear between the piston and the liner. Articulated piston withstands higher mechanical and thermal load, eliminating knocking at low temperature and scuffing at high temperature.

Cummins Celect fuel system (low-pressure fuel line) has been designed to eliminate risks of fuel leakage. Large amount of oil into and from the fuel injector prevents injector from stuck, And, the flowing fuel also cools down the ECM -the brain of the Engine, extending the service life of ECM.

By unique combination of viscosity sensor, pressure regulator and relief valve, the lubrication system automatically regulates the engine oil pressure, ensuring lubrication effects in all seasons.

The package design of engine oil thermostat, radiator and bypass valve guarantees an optimal working condition for the Engine and effectively prolongs the oil change interval. 4-step pressure regulator for turbocharging system can improve response speed to prevent overheart, overspeed and abnormal wear

Great Power, Pioneer of Energy Saving

Cummins’ proprietary Celect fuel system, which injection pressure exceeds 1800bar, utilizes single-cylinder, four-valve technology. Good fuel atomization and full combustion ensure high fuel economy while maintaining great power.

The speed of silicon oil fan can be controlled electronically based on engine temperature, saving fuel and reducing noise.

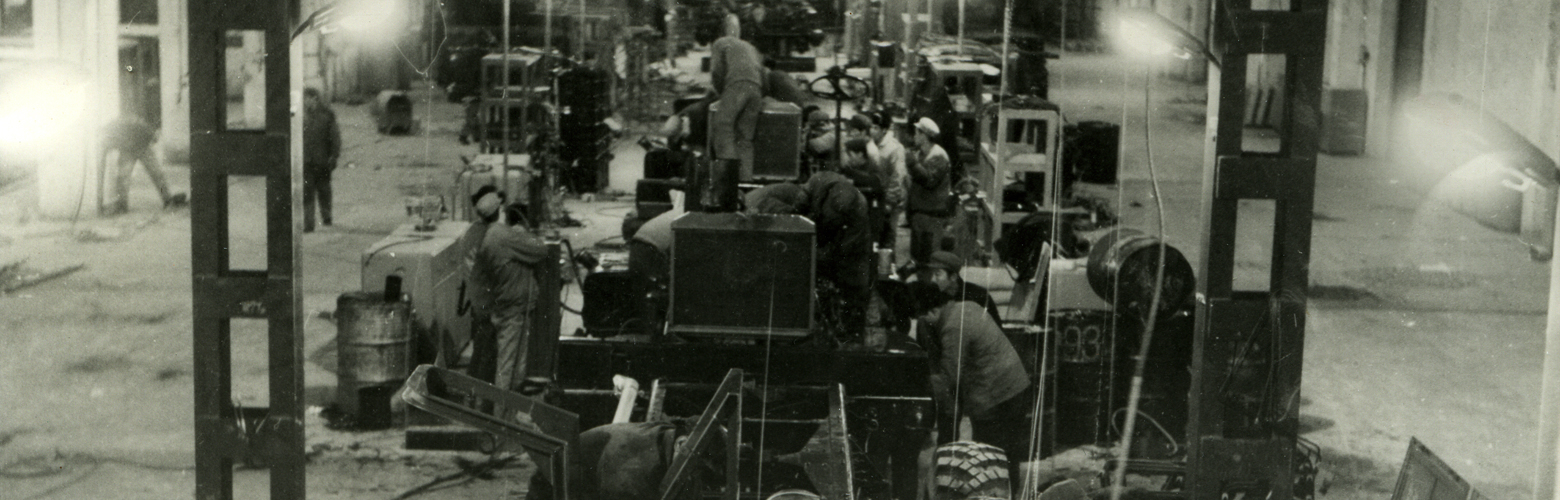

Quality Manufacturing Being Trusted Widely

As a global model factory of Cummins, XCEC builds up excellent capability by using state-of-art manufacturing equipment, standard processes, sophisticated testing devices and strict quality control procedures.

Moreover, XCEC shares excellent quality parts globally to maintain consistent quality.

It strives to maintain the pure bloodline of the products through strict processes and therefore won trusts of millions of users with reliable quality.

The Engine is regarded as the most trusted heavy duty engine by truck drivers. The red “heart" embodies hundred-year history of Cummins’ quality, and also will witness a promising future of manufacturing in China More reliable, more economical and more powerful.

This is the excellent quality of Cummins ISM 11 flagship power from the U.S., as you expect.